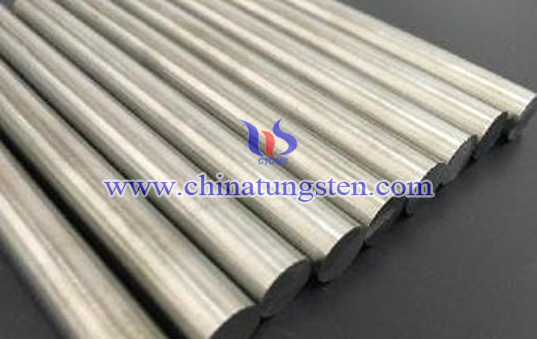

Tungsten Rods for Counterweight and Semiconductor

Advantages of tungsten in tungsten guide rods Tungsten more than one and a half times the weight of lead, and it was able to pack a lot of weight into a small area in the car body. Lead melts at about 600 degrees, a temperature you can reach with a propane torch. But tungsten melts at 6000 degrees, so melting it into the car body isn’t an option. Instead I had to pack the beads in, shaking the car to get the beads to settle.

What is a tungsten rod for the use of semiconductor?

A tungsten rod is a basic part for manufacture of a probe pin. It should not have defectiveness in straightness and in cut surface. A probe pine is the core part of a probe card which is inspection equipment. The probe pin is produced through chemical etching manufacturing process and mechanical manufacturing process. The probe card connects at the same time each signal wires of a tester with each pad of a wafer by chip unit so that a wafer tester can really test the function and capacity of a wafer.

Kind of Tungsten rod for semiconductor

Raw tungsten + wire plated by Ni

Raw tungsten (Not plated by Ni)

General tungsten + wire plated by Ni

Tungsten guide rods offer the ultimate in recoil reduction. Tungsten weighs more than double